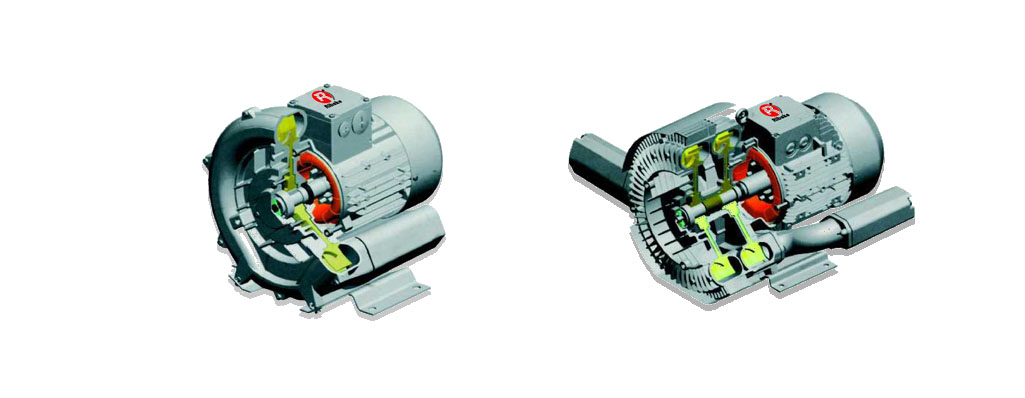

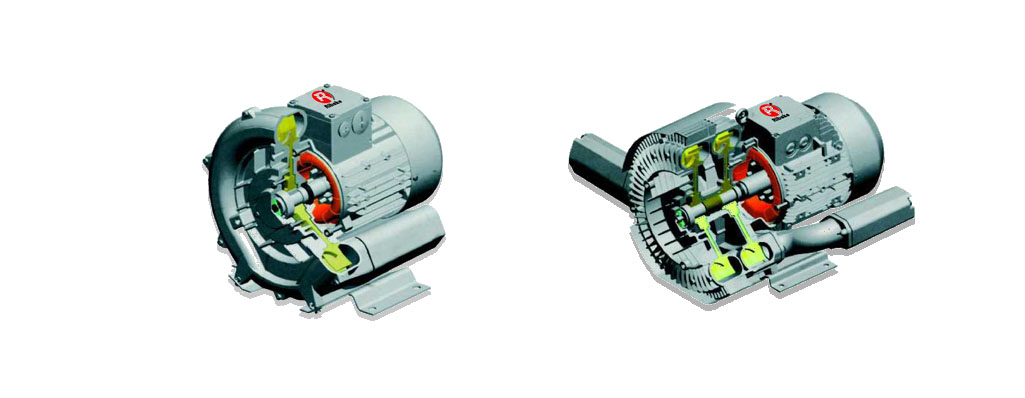

The mechanical wear of the vortex high-pressure fan is very small, because there are no other mechanical contact parts except the bearing, so of course the service life is also very long. As long as it is under normal use conditions, 3 to 5 years is no problem at all ; Maintenance-free use; its wearing parts are only two bearings, and basically do not need to be maintained within the warranty period; compared with similar fans, its running noise is lower, the introduction of ultra-quiet high-pressure fans: if the pump body is integral Die-casting, and using the shock-proof mounting foot, then it has very low requirements for the installation foundation, and it can even run normally without fixing the foot, which is very convenient and saves installation costs and installation cycles;

As an important equipment in the wet limestone-gypsum desulfurization and forced oxidation process, the noise of the oxidation fan is always a problem that designers cannot avoid. Research and practice in various fields have proved that adding a soundproof cover is a better measure to reduce the noise of an oxidation fan.

1. Functions that the soundproof cover should have

Through consideration of all aspects in the operation of the oxidation fan, the soundproof cover should have the following functions:

1. The soundproof cover must meet the environmental protection standards for fan noise emission;

2. When the oxidation fan and the motor are running, the temperature in the soundproof cover is relatively high due to the heat dissipation of the fan. It must be controlled to ensure the normal use of the motor and the fan. Ventilation and cooling and airtight sound insulation form a contradiction, and both must be taken into account in the design. , Strive to be reasonable;

3. Rainproof and waterproof to ensure the normal operation and service life of the equipment;

4. Under the premise of not disassembling, complete the daily maintenance of equipment, and strive to be simple and convenient during overhaul disassembly and equipment update.

2. The components and functions of the vortex high pressure fan sound insulation cover

The soundproof cover is mainly composed of a soundproof cover body, an axial fan and an overhaul door. Generally, the soundproof cover is divided into two parts vertically along the fan axis. One part of the flue gas outlet side is fixed, and the other part is movable and can be separately butted. The bottom of the fan uses rubber damping pads, the top interface is lapped to prevent leakage, and the side interface is fixed with bolts. After the two pieces are connected, they are pressed against each other to ensure tightness.

The type of equipment installation determines the location and size of the cooling vent. The main function of ventilation is to cool the fan and avoid the influence of the fan shell on the motor. Therefore, the rear of the motor is 10cm below the motor on the side opposite to the fan, above the fan case Open one vent hole. The size of the vent hole should be limited to 15-20m/s according to the blast volume to ensure the blast volume. At the same time, for the purpose of sound insulation, the ventilation suction port is made of muffler short section of 1m. In order to greatly attenuate the noise, a 90-degree elbow is added before the short section, and the elbow mouth is downward. The manufacturing method is the same as the main body of the soundproof cover. In this way, the main noise source of the blower can be controlled, noise reduction, energy saving and consumption reduction are realized.

3. Operation example of multiple sets of FGD device oxidation fan soundproof cover

After using the soundproof cover, it can effectively control the noise of the oxidation fan to meet the requirements of the environmental protection department, and successfully solve the problem of dissatisfaction with the noise emission of the power plant. Therefore, the noise reduction measures of the oxidation fan in this project recommend the use of a soundproof cover, and the indoor layout of the oxidation fan also has a certain effect on noise reduction.

WeChat scan

WeChat scan